Demystifying Welding Symbols: Your Guide to AWS Symbol Interpretation

Welding is a cornerstone of numerous industries, from construction and shipbuilding to aerospace and manufacturing. Ensuring consistent, high-quality welds requires a universal communication system. Enter American Welding Society (AWS) welding symbols! These standardized symbols, outlined in AWS A2.4, provide a concise and efficient way to communicate detailed weld information on drawings and specifications.

What are AWS Welding Symbols?

Imagine a visual language for welding, conveying crucial weld information in a compact symbol. That's the power of AWS welding symbols. These graphical representations specify various aspects of a weld, including:

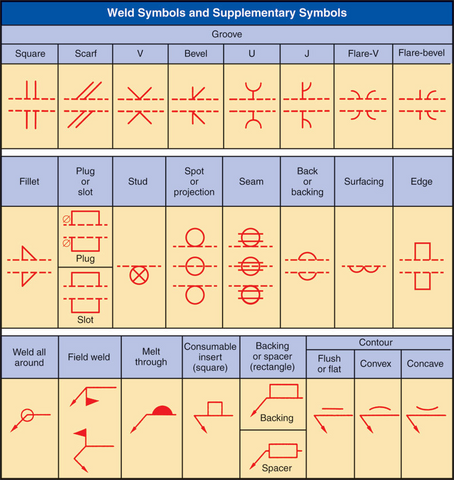

- Weld type: Groove, fillet, plug, slot, etc.

- Weld size: Dimensions like leg length for fillets and depth for grooves.

- Weld location: Where the weld needs to be placed on the joint.

- Weld requirements: Additional details like weld finish, root opening, and backing.

Understanding the Anatomy of a Welding Symbol

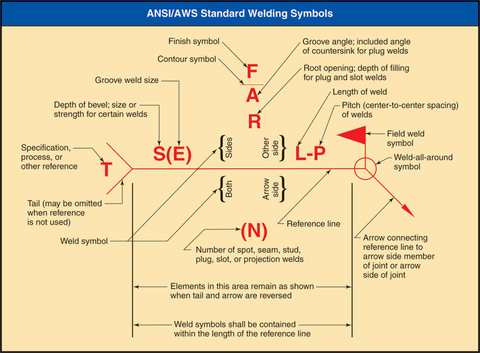

AWS welding symbols are composed of several key elements:

- Reference line: A horizontal line serving as the symbol's foundation.

- Arrow: Points to the member where the weld is made.

- Basic weld symbol: Depicts the weld type (e.g., triangle for fillet, square for groove).

- Dimension lines and values: Specify weld size and other required dimensions.

- Supplementary symbols: Provide additional information like weld finish, contour, and process.

- Tail: An optional extension used for notes and specifications.

The Importance and Usage of the AWS Welding Symbol Arrow

The arrow is a critical element of the AWS welding symbol. It points to the member where the weld is made, ensuring the weld is placed in the correct location.

The arrow can also indicate the weld's direction of travel. For instance, a fillet weld arrow pointing upwards indicates a weld from the bottom to the top.

Beyond its primary function, the arrow can convey more information, including:

- Side of the joint: A groove weld arrow pointing to the left side indicates the weld should be made on the left side.

- Type of weld: A plug weld arrow pointing to the joint's center indicates a plug weld at that location.

Understanding the arrow's importance and usage helps welders place welds accurately and in accordance with specified requirements.

Benefits of Using AWS Welding Symbols

- Improved communication: Standardized weld information reduces errors and misinterpretations.

- Enhanced efficiency: Saves time and space on drawings compared to textual descriptions.

- Global understanding: Recognized worldwide, facilitating collaboration across borders.

- Quality assurance: Consistent interpretation ensures welds meet specified requirements.

Learning Resources for AWS Welding Symbols

The American Welding Society offers a wealth of resources for learning and understanding AWS welding symbols:

- AWS A2.4 Standard Symbols for Welding, Brazing, and Nondestructive Examination: The official guide to AWS welding symbols.

- AWS Online Training: Interactive courses and modules on reading and interpreting welding symbols.

- AWS Certification: Programs like Certified Welding Inspector (CWI) validate your knowledge of welding symbols.

Mastering the language of welding unlocks a world of opportunities. By understanding and utilizing AWS welding symbols, you can elevate your welding skills, ensure quality work, and contribute to the success of your projects.

Additional Resources:

- American Welding Society: https://www.aws.org/: https://www.aws.org/

- AWS Symbols Online Training: https://m.youtube.com/watch?v=Nw9aVwu1MkY: https://m.youtube.com/watch?v=Nw9aVwu1MkY

- AWS Certified Welding Inspector: https://www.aws.org/: https://www.aws.org/